Summary

In the modern era of manufacturing and digital machining, CNC (Computer Numerical Control) systems have become the backbone of precision engineering. As industries shift toward automation and digitally controlled machining processes, the demand for skilled CNC operators and programmers has skyrocketed. However, hands-on training on real CNC machines is expensive, time-consuming, and sometimes risky. This is where CNC simulators step in, offering a powerful and safe virtual environment where users can learn, practice, and refine their CNC programming skills. These simulators replicate real CNC operations in a digital workspace, making them essential tools for education, professional training, and industrial skill development.

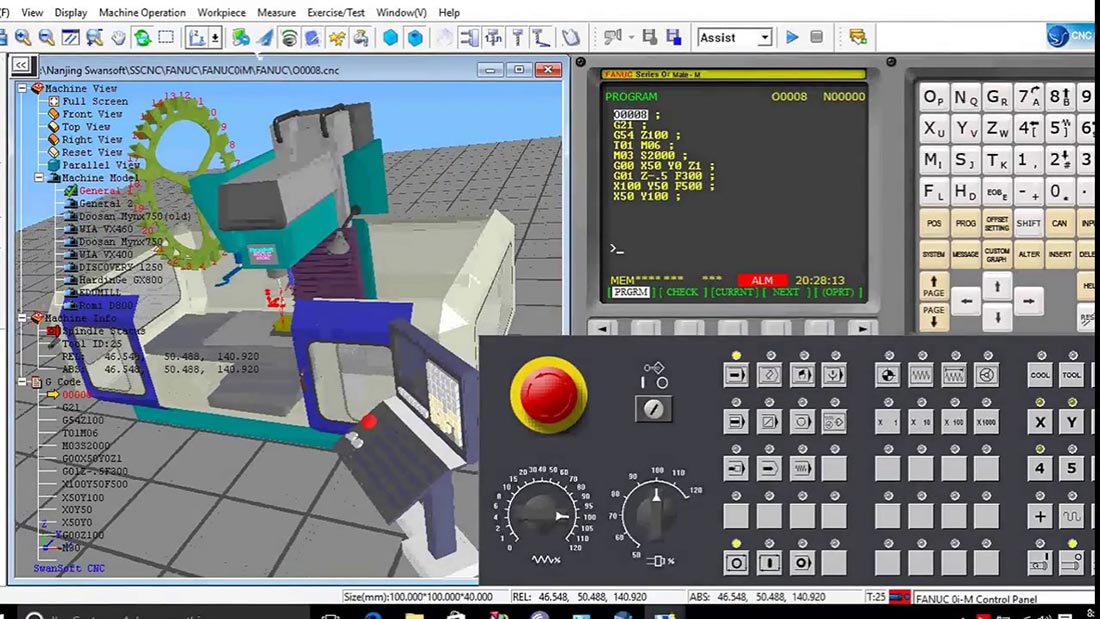

CNC simulators are advanced software systems designed to emulate the behavior of real CNC machines on a computer interface. These programs provide a graphical interface where users can create, test, and troubleshoot CNC programs using G-code or M-code, just as they would on a physical machine. The visual feedback and simulation tools enable users to understand tool paths, spindle movement, material removal, and potential errors in a highly interactive manner. The simulator environment is particularly useful in preventing costly mistakes and collisions by identifying problems before actual machining occurs. By simulating CNC operations, learners and professionals can develop a strong foundation in CNC technology without the need for physical materials or machinery.

Safe and Risk-Free Training for Beginners

One of the most significant advantages of using CNC simulators is the ability to train without damaging expensive machinery or wasting valuable materials. In real-world settings, programming errors can lead to tool breakage, machine damage, or poor-quality output. Simulators eliminate this risk by allowing users to experiment with different codes and setups without real-world consequences. This risk-free environment encourages students to explore advanced techniques, make mistakes, and learn from them, which accelerates their understanding of the CNC workflow.

Cost-Effective Learning and Industrial Application

Training on actual CNC machines requires a substantial financial investment in equipment, raw materials, and machine maintenance. CNC simulators reduce these costs dramatically by offering a fully digital training experience. Institutions and industries can deploy multiple licenses of simulation software without the need to purchase multiple machines. Furthermore, businesses can use simulators to pre-test their programs before running them on production lines, ensuring process accuracy and minimizing downtime or material waste.

Realistic Machine Behavior and Visualization

High-end CNC simulators replicate not only the programming but also the physical behavior of machines. This includes tool acceleration, deceleration, cutting forces, spindle speeds, and machine limitations. Users can visualize the toolpath in 2D or 3D, analyze the cutting process layer by layer, and simulate machining operations such as drilling, turning, milling, or grinding. This level of realism helps bridge the gap between digital training and physical implementation, making users industry-ready faster and more efficiently.

Educational Simulators for Students and Trainees

Educational CNC simulators are designed specifically for classroom environments, vocational training centers, and online learning platforms. These simulators usually come with interactive tutorials, step-by-step guidance, and a user-friendly interface. They often include simplified virtual controls that mimic the basic functions of a CNC machine and help students grasp fundamental concepts such as coordinate systems, axis movements, tool selection, and basic G-code syntax. Popular educational simulators include FANUC Simulator, NC Viewer, and CNCSimulator Pro.

Industrial-Grade Simulators for Professionals

Professional or industrial simulators are built for advanced users such as CNC programmers, machinists, and engineers. These simulators offer full support for complex G/M code programming, post-processing, multi-axis machining, and customized machine configurations. They support a wide range of machine types, including lathes, mills, and routers. Features such as collision detection, material simulation, and virtual commissioning make them ideal for reducing errors in production environments. Examples include Siemens Sinutrain, Heidenhain Interactive Training, and NCSimul.

Web-Based and Mobile CNC Simulators

With increasing demand for remote learning and mobile accessibility, many CNC simulators are now available online or as mobile applications. These lightweight versions do not require high-end hardware or installation and can run directly in a browser or smartphone. While they may lack some of the advanced capabilities of desktop versions, they are excellent tools for quick code testing, on-the-go training, and conceptual learning. Users can simulate tool paths, import CAD/CAM files, and visualize code output through interactive panels.

Multi-Axis and Multi-Tool Support

Modern machining often involves complex multi-axis operations such as 4-axis or 5-axis milling. A capable CNC simulator must support these advanced configurations, enabling users to simulate synchronized movements, rotary tables, and compound angles. Similarly, support for multiple tools allows users to define tool changes, offsets, and cutting strategies accurately, simulating the complete machining cycle from start to finish.

Error Detection and Debugging Tools

Debugging CNC programs manually is a challenging task, especially when dealing with long G-code scripts. CNC simulators come equipped with powerful debugging tools that highlight syntax errors, out-of-bound movements, tool collisions, and feedrate anomalies. The simulation interface shows exact points of failure in real time, guiding users to fix problems and optimize code before running it on actual machines. This drastically improves efficiency, reduces trial-and-error, and ensures a smooth machining process.

Customization and Post-Processor Integration

CNC simulators that offer customization options allow users to emulate specific machine models, tool libraries, and control panel layouts. This makes the transition from simulation to real production seamless. Advanced simulators also integrate with post-processors used in CAM software like Mastercam, Fusion 360, or SolidWorks, ensuring the output code matches the machine’s requirements exactly. These features are particularly important for companies that use proprietary setups or complex machines.

Virtual Commissioning and Digital Twin Capabilities

CNC simulators can be connected to IoT platforms and machine sensors to create a digital twin, a virtual replica of the real machine. This allows engineers to run diagnostics, predict machine behavior, and simulate full production runs in a virtual environment. Virtual commissioning reduces deployment time and increases reliability by validating system integration before physical setup. It also supports predictive maintenance by simulating wear and usage patterns, reducing machine downtime.

Integration with CAD/CAM and Smart Systems

Modern CNC simulators seamlessly integrate with CAD/CAM platforms to create a unified workflow. Users can design a part, generate toolpaths, simulate the operation, and verify the outcome all within a single environment. This interoperability is vital for rapid prototyping, mass customization, and agile manufacturing processes. Moreover, the simulators’ ability to collect and analyze machine data helps in decision-making and process optimization, which are core pillars of Industry 4.0.

Final Thoughts on the Role of CNC Simulators

CNC simulators have become indispensable tools in both education and professional machining environments. They provide a safe, cost-effective, and realistic platform for mastering CNC programming and machine operation. By reducing the risk of damage, increasing accessibility to training, and enabling advanced simulations, they play a crucial role in shaping the next generation of CNC machinists and engineers. As manufacturing continues to digitize, CNC simulators will remain at the forefront of skill development, innovation, and operational excellence.